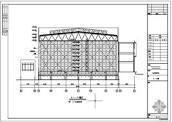

Steel roof trusses

Price nan INR/ Kilograms

Steel roof trusses Specification

- Material Grade

- IS 2062 E250, E350, ASTM A36 or Equivalent

- Machines Type

- Welded & Bolted Structural Assembly

- Installation Type

- On-site Assembly, Bolted or Welded Connection

- Color

- Grey, Silver, or Customized

- Purity

- Commercial Grade Steel

- Thickness

- 3mm to 12mm or as per Design

- Usage

- Roof Framing for Large Span Structures

- Form

- Prefabricated Steel Members

- Load Capacity

- Designed as per IS 800/IS 875/Client Requirements

- Application

- Industrial Sheds, Warehouses, Commercial Buildings, Sports Complexes, Factories

- Features

- High Load Bearing, Weather Resistant, Low Maintenance

- Diameter

- Typically Not Applicable, Sectional Profile Sizes Depend on Design

- Product Type

- Steel Roof Trusses

- Main Material

- High-Quality Mild Steel or Structural Steel

- Surface Treatment

- Hot Dip Galvanized / Painted / Primer Coated

- Size

- Customizable as per Design, Common spans range from 6m to 30m

- Weight

- Varies as per Design Specification (Typically 35-60 kg/m)

- Feature

- Corrosion Resistant, High Strength, Durable, Precise Fabrication

- Shape

- Triangular / Pitched / Parallel Chord

- Design Standard

- IS 800, IS 875, BS 5950, AISC, ASCE or as per Requirement

- Fabrication Service Type

- Custom Fabrication, On-site Installation, Erection Service

- Accessories

- Truss Bracing, Purlins, Anchor Bolts, Roofing Sheets as per Requirement

- Lifespan

- 25-50 Years with Proper Maintenance

- Corrosion Protection

- Red Oxide Primer and Optional Epoxy or PU Coating

- Maintenance

- Minimal, Regular Inspection Recommended

- Environmental Compliance

- Meets Applicable Green Building Standards

- Connection Method

- Gusset Plate, Bolted Connections, Full/Partial Welding

- Delivery Condition

- Knocked Down (KD) Form for On-site Assembly

- Joint Type

- Welded, Bolted, or Combination

- Fire Resistance

- Available with Fireproof Coating on Request

- Span Range

- Up to 30 meters or Customized

- Fabrication Product

- Prefabricated Steel Roof Truss Sections

- Fabrication Process

- Computer-Aided Design, CNC Cutting, Welding, Drilling, Painting

- Wind/Snow Load Compatibility

- Engineered per Site Specific Loads

Steel roof trusses Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Kilograms Per Day

- Delivery Time

- 1-3 Minutes

- Sample Available

- No

- Main Domestic Market

- All India

About Steel roof trusses

Steel Roof Trusses

We fabricators ofSteel Roof Trussesbased on clients requirements. We can fabricated it for Pre- Fabricated Buildings as well as steel buildings.

Features:

- Reliable

- Quality product

Engineered for Versatility and Strength

Our steel roof trusses are crafted for adaptability across a variety of applications, from factories and commercial structures to warehouses and sports complexes. Manufactured from high-quality IS 2062 E250/E350 or ASTM A36 steel, each truss is custom-designed to your projects specifications, ensuring optimal load distribution, wind, and snow load compatibility. Advanced fabrication techniques such as CNC cutting and computer-aided design strengthen reliability and precision, regardless of span and design complexity.

Reliable Protection and Enduring Performance

Ensuring long-lasting service, the trusses are factory-treated with red oxide primer and can be upgraded to epoxy or PU coatings for enhanced corrosion protection. Fire-resistant coatings are available to meet local safety codes. Precision fabrication with advanced welding and bolting assembly ensures structural resilience, while regular inspections and minimal maintenance keep the system performing for 2550 years.

FAQs of Steel roof trusses:

Q: How are steel roof trusses installed, and what is included in the service?

A: Steel roof trusses are delivered in knocked-down (KD) form for on-site assembly. Installation services can be provided, including erection, bracing, purlins, anchor bolts, and roofing sheets. The connection methodwhether bolted, welded, or a combinationis chosen based on your projects requirements.Q: What are the advantages of using welded, bolted, or combination joints for trusses?

A: Welded joints offer seamless strength, while bolted joints enable easy assembly and future adjustments. Combination joints merge the benefits of both, providing robust, precise connections suitable for various design and load conditions. The choice depends on your structural and logistical needs.Q: When should I consider adding fireproof or enhanced corrosion protection to my trusses?

A: Fireproof coatings are advised when building codes require additional fire resistance, such as in industrial or public spaces. Enhanced corrosion protection (epoxy or PU coatings) is recommended for humid, coastal, or chemically exposed environments to extend the lifespan and ensure consistent performance.Q: Where can these steel roof trusses be applied?

A: They are ideal for large-span applications such as warehouses, industrial sheds, commercial buildings, factories, sports complexes, and similar structures where robust and long-lasting roof framing is essential.Q: How does the customization process for steel roof trusses work?

A: Each truss is designed using computer-aided tools, taking into account your specific architectural, load, and environmental requirements. Spans, section profiles, thickness, and surface treatments are tailored to your project, ensuring compliance with standards and optimal performance.Q: What maintenance is required for steel roof trusses?

A: Maintenance is minimal, typically involving periodic inspections to check for paint degradation, bolt tension, or corrosion, especially in challenging environments. With proper care, these trusses can have a service life of 2550 years.Q: What are the environmental benefits of your steel roof trusses?

A: Manufactured from commercial-grade, recyclable steel, our trusses meet relevant green building standards. The durable surface treatments and long service life further contribute to sustainable construction practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Building & construction materials Category

Civil Design Works

Minimum Order Quantity : 100 Square Foots

Usage : Infrastructure Development

Main Material : Concrete, Steel, RCC

Purity : 80100%

Color : Grey, As required

Installation Type : On Site

"We are mainly dealing in South India"

The company is registered in the following address:

Samy Plaza Complex, Meenakshi Marriage Hall, 150/17, Velachery Main Road, East Tambaram,

Chennai-600 059,

Phone: +914422390524, Fax: +914443111374

Mobile:+919940047425

FABRICATION, TOOL ROOM AND MACHINE SHOP

ADDRESS Plot #30, SIDCO Womens Industrial Park,

Thirumulaivoiyal, Vellanur Village,

Kattur, Chennai-600 062

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry