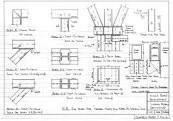

Structural steel design work

Structural steel design work Specification

- Processing

- CNC Cutting, Welding, Drilling, Shot Blasting

- Grade

- ASTM A36, SS400, S275JR, Q235B

- Capacity

- Up to 200 Tons/Month

- Application

- Steel structures, Industrial plants, Warehouses, High-rise buildings

- Condition

- NEW

- Tolerance

- 2 mm

- Dimension (L*W*H)

- Customizable, e.g. 6000 mm x 3000 mm x 20 mm

- Color

- As per client specification

- Load Bearing Capacity

- As per project specifications

- Connection Type

- Bolted / Welded joints

- Corrosion Resistance

- Available on request

- Design Standard

- IS 800 / AISC / BS EN standards

- Surface Finish

- Primer coated / Painted / Galvanized

- Customization

- Available as per drawings and requirements

- Packaging

- Standard export packaging or as required

- Welding Type

- MIG / TIG / SMAW as per standards

- Material

- Mild steel / Structural steel

Structural steel design work Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 1-3 Months

- Main Domestic Market

- All India

About Structural steel design work

Structural Steel Design Work

We can also perform concrete designs for slabs, beams, foundations, equipment foundations etc.

We can generate fabrication drawings, bill of materials and also prepare specifications if required for the civil and structural works.

Precision-Engineered for Versatile Applications

Whether constructing warehouses, industrial plants, or high-rise buildings, our structural steel components are engineered to meet exact specifications. We utilize leading standards like IS 800, AISC, and BS EN to ensure every piece is up to code, with load-bearing capabilities defined by your projects requirements.

Advanced Processing for Lasting Quality

Using state-of-the-art CNC cutting, robotic welding, and thorough shot blasting, each component is crafted for durability and accuracy. Our processes provide clean finishes and consistent results, supporting both bolted and welded connections as your design demands.

Finishes and Protection Tailored to Your Needs

Choose from primer coating, painting, or galvanization to guard against corrosioneven custom color options are available. Special corrosion-resistant treatments can be requested to suit the environmental demands of your installation, maximizing the longevity of your structures.

FAQs of Structural steel design work:

Q: How is the structural steel customized for specific projects?

A: Customization is achieved by working directly from client drawings and specific requirements. Dimensions, connection types, grades, surface finishes, and load capacities are tailored precisely to your project using advanced processing techniques and industry standards.Q: What materials and standards do you use for steel design?

A: We work primarily with mild steel and structural steel grades such as ASTM A36, SS400, S275JR, and Q235B, adhering to industry standards like IS 800, AISC, and BS EN to ensure compliance and performance.Q: When should corrosion-resistant finishes be requested?

A: Corrosion-resistant treatments, such as galvanization or specialized coatings, are recommended for structures exposed to harsh weather, chemicals, or moisture. Please specify these needs early in the design phase to ensure optimal protection.Q: Where can your structural steel components be used?

A: Our products are suitable for a variety of applications including steel structures, industrial plants, warehouses, and high-rise buildings, meeting both domestic and international requirements.Q: What is the process for ensuring dimensional accuracy and load capacity?

A: We use CNC cutting and precise quality control measures to maintain tolerances within 2 mm. Load-bearing capacities are determined according to project specifications and verified throughout the design and manufacturing stages.Q: How are joints and connections handled in your designs?

A: Depending on the project needs, we offer both bolted and welded joints, performed using appropriate welding techniques such as MIG, TIG, or SMAW, all in line with global standards.Q: What are the benefits of choosing your structural steel services?

A: Clients benefit from customized solutions, adherence to global standards, diverse finishing options, corrosion resistance on request, and scalable manufacturing capacityall ensuring durability, safety, and cost-effectiveness for every project.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Storage Tanks Category

Industrial MS Vessel

Minimum Order Quantity : 1 Unit

Grade : Industrial Grade

Product Type : Vessel

Application : For Industrial Use

Capacity : 500010000 Kg/hr

Industrial Drain Tanks

Price Range 100.00 - 150.00 INR / Kilograms

Minimum Order Quantity : 1 Unit

Grade : Industrial Grade

Product Type : MS and SS Tanks

Application : For Industrial Use

Capacity : 100010000 Kg/hr

Metallic Chemical tanks

Minimum Order Quantity : 1 Unit

Grade : Industrial Grade

Product Type : Tanks

Application : For Industrial Use

Capacity : 500010000 Kg/hr

Industrial Chemical Vessels

Price Range 100.00 - 200.00 INR / Kilograms

Minimum Order Quantity : 1 Unit

Grade : Industrial Grade

Product Type : Vessels

Application : For Industrial Use

Capacity : 10000 Tons/year

"We are mainly dealing in South India"

The company is registered in the following address:

Samy Plaza Complex, Meenakshi Marriage Hall, 150/17, Velachery Main Road, East Tambaram,

Chennai-600 059,

Phone: +914422390524, Fax: +914443111374

Mobile:+919940047425

FABRICATION, TOOL ROOM AND MACHINE SHOP

ADDRESS Plot #30, SIDCO Womens Industrial Park,

Thirumulaivoiyal, Vellanur Village,

Kattur, Chennai-600 062

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry