Mild Rubber Lined MS tanks

Mild Rubber Lined MS tanks Specification

- Material

- Mild Steel (MS) with Hard Rubber Lining

- Capacity

- Customizable; typically 500 L to 50,000 L or as per requirement

- Shape

- Cylindrical / Rectangular

- Application

- Chemical Storage, Electroplating, Water Treatment, Acidic and Alkali Solutions

- Power

- N/A (Non-powered Tank)

- Voltage

- N/A (Non-electrified)

- Manhole/Access Ports

- Provided with gasketed covers for easy inspection and cleaning

- Leakproof Design

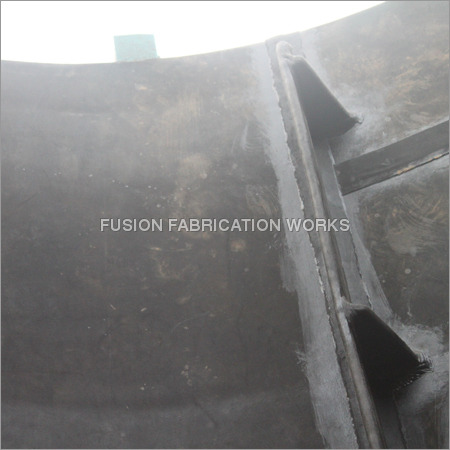

- 100% leakproof construction with fully vulcanized lining

- External Finish

- Anti-corrosive paint or primer

- Support/Base

- Mounted on steel saddles or concrete base as per design

- Testing

- Hydro-tested for leakproof guarantee

- Lining Thickness

- Typically 3 mm to 6 mm (customizable depending on application)

- Internal Finish

- Seamless cured rubber lining for chemical resistance

- Connections

- Inlet, Outlet, and Overflow Nozzles as per client specifications

- Compliance

- Manufactured as per IS or international standards

- Operating Temperature

- Up to 70C depending on lining material

- Corrosion Resistance

- Excellent due to high-grade rubber lining

Mild Rubber Lined MS tanks Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 1-3 Months

- Main Domestic Market

- All India

About Mild Rubber Lined MS tanks

Mild Steel Rubber Tanks

We are one of the most reputed manufacturers and exporter of a wide assortment of Mild Steel Rubber Tanks which are available in various capacities and specifications in the market. In our manufacturing procedure, we use quality approved raw material and technically advanced technologies and we are supported by the capacious warehouses that assist us to safely secure the entire product range.

Features:

- Precision engineered

- Different capacity

- Precision engineered

Specifications:

- Height : 6 to 10 Meters

- Diameter: 1 to 3 Meters

- Horizontal & Vertical execution with our without rubber lining

- Capacity: As per client requirement

- Industrial Chemical Vessels including Jacketed Vessels

- Type of Rubber: As per client requirement example natural/nitrile/butile

Premium Chemical Resistance

Our MS tanks come equipped with seamless, high-grade rubber linings specifically designed to resist chemicals and aggressive solutions. This makes them ideal for storing acids, alkalis, or other corrosive materials. The cured rubber layer is seamlessly bonded to the mild steel, ensuring total protection and long service life without risk of contamination or corrosion.

Customized for Your Process

Each tank is tailored to meet your requirements, offering various capacities, inlet/outlet arrangements, and manhole designs. Whether you need a cylindrical unit for chemical processing or a rectangular tank for water treatment, we provide flexible configurations to suit application demands. All tanks are designed and manufactured according to IS or international quality standards for complete reliability.

Dependable Leakproof Design

With a fully vulcanized rubber lining and gasketed manholes, these tanks provide a 100% leakproof solution. Hydro-testing is conducted before dispatch to guarantee integrity, while external anti-corrosive coatings help the tank withstand harsh environments. Mounting options on steel saddles or concrete bases ensure robust installation at your facility.

FAQs of Mild Rubber Lined MS tanks:

Q: How are mild rubber lined MS tanks manufactured to ensure corrosion resistance?

A: Mild rubber lined MS tanks are fabricated from mild steel and then lined internally with a seamless, high-grade rubber layer (usually 3 mm to 6 mm thick) that is fully vulcanized. This process creates a uniform, chemically resistant barrier, protecting the steel from corrosive contents.Q: What industries and applications are these tanks suitable for?

A: These tanks are ideal for chemical storage, electroplating, water treatment, and handling acidic or alkaline solutions. They are commonly used in industries such as chemical processing, power generation, pharmaceuticals, and wastewater treatment.Q: When should a customized rubber lined MS tank be selected over standard storage tanks?

A: A customized rubber lined MS tank is recommended when handling highly corrosive substances or when specific capacity, nozzle arrangement, or dimensions are required to fit unique site conditions or process needs. Rubber lining ensures extended tank life and safe storage of aggressive chemicals.Q: Where can these tanks be installed, and how are they supported?

A: These tanks can be installed both indoors and outdoors, on steel saddles or concrete bases, depending on facility design. Proper support ensures structural stability and safe operation in a variety of industrial environments.Q: What testing is carried out to guarantee leakproof performance?

A: Each tank undergoes hydro-testing, where it is filled with water and pressurized to test for leaks. This process certifies that the tank and its lining are 100% leakproof before reaching the customer.Q: What are the main benefits of using a rubber lined MS tank for chemical storage?

A: The main advantages include excellent chemical and corrosion resistance, a leakproof design, easy maintenance through manholes, customizable sizes and fittings, and compliance with industry standards for quality and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Lined Tank Category

Cylindrical tank

Minimum Order Quantity : 1 Unit

Application : Water Storage

Material : Highdensity polyethylene (HDPE)

Shape : Cylindrical

Capacity : 5000 Liters

Rubber lined tank

Minimum Order Quantity : 1 Unit

Application : Chemical Storage, Electroplating, Water Treatment

Material : Mild Steel with Rubber Lining

Shape : Cylindrical/Vertical/Horizontal

"We are mainly dealing in South India"

The company is registered in the following address:

Samy Plaza Complex, Meenakshi Marriage Hall, 150/17, Velachery Main Road, East Tambaram,

Chennai-600 059,

Phone: +914422390524, Fax: +914443111374

Mobile:+919940047425

FABRICATION, TOOL ROOM AND MACHINE SHOP

ADDRESS Plot #30, SIDCO Womens Industrial Park,

Thirumulaivoiyal, Vellanur Village,

Kattur, Chennai-600 062

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry