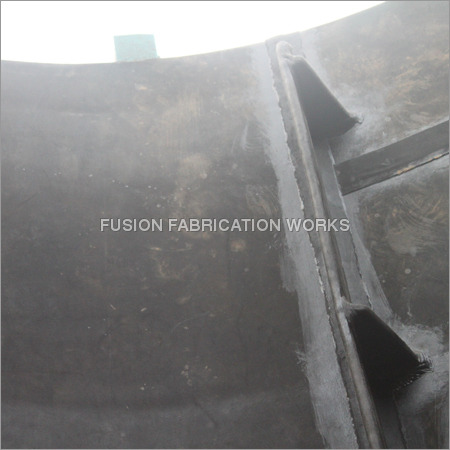

Rubber lined tank

Rubber lined tank Specification

- Material

- Mild Steel with Rubber Lining

- Shape

- Cylindrical/Vertical/Horizontal

- Application

- Chemical Storage, Electroplating, Water Treatment

Rubber lined tank Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 1-3 Months

- Main Domestic Market

- All India

About Rubber lined tank

Our range of industrial rubber linings Tanks is widely used in tanks, vessels, etc due to its superior quality. Using advanced technology, we manufacture these rubber linings Tanks in varying thickness.

Technical Specifications

Diameter | 1 to 3 Meters |

Storage Material | Water,Milk/Dairy,Chemicals/Oils,Waste |

Capacity | 5000-10000 L,Client Requirement |

Type of Rubber | Natural, Nitrile, Butile, Client Requirement |

Orientation | Horizontal & Vertical execution with our without rubber lining |

Height | 6 to 10 Meters |

Superior Protection for Corrosive Environments

Each mild steel tank is equipped with a robust rubber lining that provides outstanding protection against chemical corrosion, ensuring your materials are safely stored. These tanks are designed to resist a wide range of chemicals typically encountered in industries like electroplating, chemical storage, and water treatment, offering peace of mind and operational longevity.

Versatile Design Adapted to Your Needs

Available in cylindrical, vertical, and horizontal shapes, our rubber-lined tanks can be customized in size and design to fit various site and process requirements. This versatility enhances integration into existing systems, making them suitable for a broad spectrum of industries throughout India and beyond.

FAQs of Rubber lined tank:

Q: How does the rubber lining benefit a mild steel tank used for chemical storage?

A: The rubber lining acts as a protective barrier against harsh chemicals, preventing corrosion and extending the lifespan of the mild steel tank. This ensures chemical purity and reduces the risk of tank failure during storage or processing.Q: What shapes are available for these tanks, and how do I choose the right one for my application?

A: We offer cylindrical, vertical, and horizontal configurations. The selection depends on your space constraints, operational requirements, and the specific applicationvertical tanks are space-saving, cylindrical shapes offer efficient cleaning, and horizontal tanks are optimal for low-height installations.Q: When is it necessary to use a rubber-lined tank instead of an unlined mild steel tank?

A: Rubber-lined tanks are essential when storing or processing corrosive chemicals, as unlined mild steel is prone to rapid deterioration. Whenever chemical resistance and extended durability are critical, a rubber lining is highly recommended.Q: Where are rubber-lined tanks commonly used in India?

A: These tanks are widely utilized in industries such as chemical manufacturing, water treatment, and electroplating throughout India, providing safe and reliable storage solutions for hazardous and non-hazardous liquids alike.Q: What is the process for manufacturing a rubber-lined tank?

A: The process involves fabricating the tank body from high-grade mild steel, thoroughly sandblasting and cleaning the interior, and then precisely applying a rubber lining to ensure optimal adherence and coverage. The tank is then cured and rigorously tested for leaks and defects.Q: How should rubber-lined tanks be maintained to ensure optimum performance?

A: Routine inspection of the rubber lining for signs of wear or damage is essential. Tanks should be cleaned using appropriate solutions that do not degrade the rubber, and regular maintenance ensures the longevity and safety of the tank.Q: What are the key advantages of choosing an Indian exporter and manufacturer for rubber-lined tanks?

A: Indian suppliers offer competitive pricing, extensive customization, and adherence to international quality standards. By choosing a reputable Indian exporter or manufacturer, clients also benefit from responsive service and local expertise, ensuring reliable support throughout the tanks lifecycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Lined Tank Category

Mild Rubber Lined MS tanks

Minimum Order Quantity : 1 Unit

Capacity : Customizable; typically 500 L to 50,000 L or as per requirement

Application : Chemical Storage, Electroplating, Water Treatment, Acidic and Alkali Solutions

Material : Mild Steel (MS) with Hard Rubber Lining

Shape : Cylindrical / Rectangular

Voltage : N/A (Nonelectrified)

Cylindrical tank

Minimum Order Quantity : 1 Unit

Capacity : 5000 Liters

Application : Water Storage

Material : Highdensity polyethylene (HDPE)

Shape : Cylindrical

"We are mainly dealing in South India"

The company is registered in the following address:

Samy Plaza Complex, Meenakshi Marriage Hall, 150/17, Velachery Main Road, East Tambaram,

Chennai-600 059,

Phone: +914422390524, Fax: +914443111374

Mobile:+919940047425

FABRICATION, TOOL ROOM AND MACHINE SHOP

ADDRESS Plot #30, SIDCO Womens Industrial Park,

Thirumulaivoiyal, Vellanur Village,

Kattur, Chennai-600 062

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry